Your aluminum parts are our mission.

ALUMINUM SPECIALIST - One-stop solution provider

DE own foundries for aluminum casting, each foundry has it own machining shop. Machining shop for high precision machining is operated individually.

Aluminum casting plus machining is our basic product line. Clients have options of sand casting, gravity casting, die casting and low pressure casting, depends on alloy, mechanical property and finishing. Liquid forging can provide die casting level unit cost with forging likely properties. Another achievement is large size low pressure casting part up to 3.3 meter.

We offer low volume/high mix and large volume production in different facilities. With our engineering achievements, we can produce gravity casting parts in an high efficient way as HP die casting. Now we supply automobile industry clients high volume components, in TS16949 environment.

We cast and machine part from 0.1 kg to 200 kg (varied by casting processes), machining tolerance up to +/-0.002 in general. For large volume part, we did build up new machining line upon customer request. PPAP APQP or AS9001 FAI process are available per customer request.

With customers from TS16949, AS9100, ISO13485 environments, we have built up an advance quality control process to satisfy customers’ requirements.

Aluminum casting plus machining is our basic product line. Clients have options of sand casting, gravity casting, die casting and low pressure casting, depends on alloy, mechanical property and finishing. Liquid forging can provide die casting level unit cost with forging likely properties. Another achievement is large size low pressure casting part up to 3.3 meter.

We offer low volume/high mix and large volume production in different facilities. With our engineering achievements, we can produce gravity casting parts in an high efficient way as HP die casting. Now we supply automobile industry clients high volume components, in TS16949 environment.

We cast and machine part from 0.1 kg to 200 kg (varied by casting processes), machining tolerance up to +/-0.002 in general. For large volume part, we did build up new machining line upon customer request. PPAP APQP or AS9001 FAI process are available per customer request.

With customers from TS16949, AS9100, ISO13485 environments, we have built up an advance quality control process to satisfy customers’ requirements.

DE has built up an integrated aluminum production capacity:

- Alloy 15 years working relationship, top foundry serving military defense, aviation, high-speed train, automotive

- Extrusion 1 for low volume/high mix special requirements, 2 for large volume/low cost demands

- Casting 3 permanent casting 2 die casting 1 sand casting 1 low pressure casting 1 investment casting 1 liquid forging

- Forging 2 facilities, precision forging and hot forging

- Precision machining 2 precision machining operations, most foundries workshops have machining capacity

- Fabrication 2 operations

- Stamping 2 facilities

- Coating Local long term sub-contractors

NEW

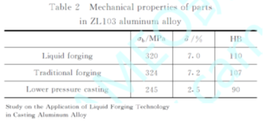

Liquid Forging process helps deliver a cost-effective, efficient way to process high-quality aluminum alloy products.

Liquid forging provides forging properties with same cost of traditional casting. It even can substitute some iron casting part with 1/3 weight.

Liquid Forging offers more flexibility in design for a broad range of shapes and components than any other manufacturing technique.

Liquid Forging process helps deliver a cost-effective, efficient way to process high-quality aluminum alloy products.

Liquid forging provides forging properties with same cost of traditional casting. It even can substitute some iron casting part with 1/3 weight.

Liquid Forging offers more flexibility in design for a broad range of shapes and components than any other manufacturing technique.

- Elimination of microporosity (shrinkage and porosity), due to the effect of solidification under pressure.

- Improvement in product surface finishing due to high direct pressure into mould surface.

- Capable of anodizing

- Near net shape process

- High aspect ratio features